Daily maintenance of CNC Router

1. The maintenance of the computer belongs to the brain part of the equipment. The dust in the factory will accumulate in the computer main box, especially in summer. If the computer does not dissipate heat well, it will easily burn the circuit board. In order to keep the computer running smoothly, Regular antivirus and disk defragmentation is also required.

2. It is necessary to regularly clean the screw, industrial control box, circuit board, and clean the work surface in time, including the material debris beside the guide rail and guide rail, so as to prevent the machine from jamming during the working process due to the interference of debris.

2. It is necessary to regularly clean the screw, industrial control box, circuit board, and clean the work surface in time, including the material debris beside the guide rail and guide rail, so as to prevent the machine from jamming during the working process due to the interference of debris.

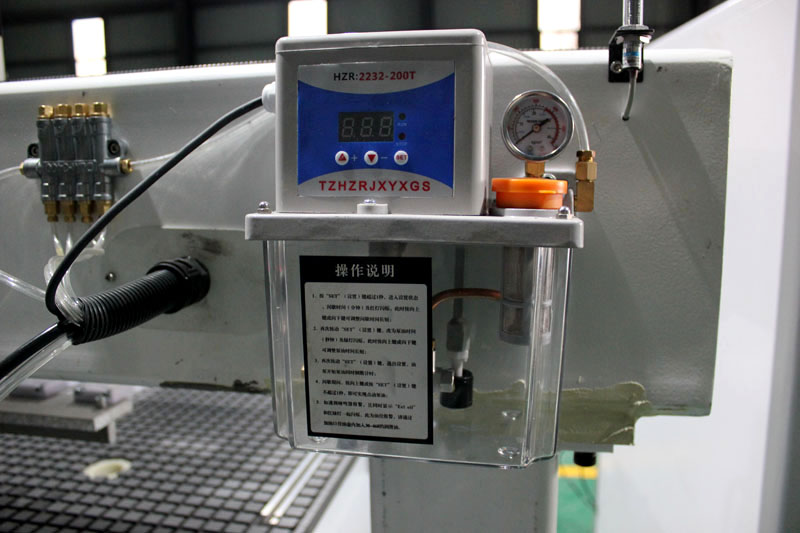

3. Walk back and forth at a slow speed after adding oil to ensure that the lubricating oil can be evenly added to the guide rail and the lead screw. If the machine is not used for a long time, it should be refueled regularly to ensure the flexibility of the transmission system. First clean the guide rail and lead screw, and use a cloth (without hair removal) to clean off the oil and material scraps on the guide rail and lead screw. If the temperature is low, you can add oil to the guide rail and screw, and antifreeze oil should be added. The refueling cycle is twice a month, that is, once every two weeks. You can also add cooling water or cooling liquid, and keep the cooling water free of impurities.

Contact: Candy Guan, Max Yuan

Phone: 008613170811607, 008618396850306

E-mail: candyguan@goodcutcnc.com

Whatsapp:008613170811607, 008618396850306

Add: A2 Block, Sanqing Shiji Caifu center, High-tech district, Jinan City, Shandong Province, China

We chat