Mode: Full automatic

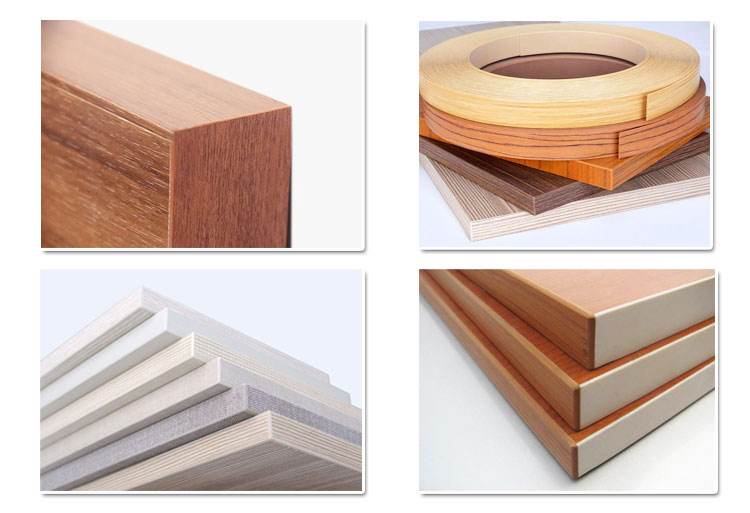

Material: PVC, Acrylic, Veneer

2.2kw pre-milling power

one year warranty

Product description: Standard function: Gluing, End cutting, Fine trimming, Scraping, Buffing Optional Functions: Premilling,Grooving,Rough trimming Application: Kitchen cabinet, wardrobe, office table One year warrant

1.Safety and thickness limitation ----Avoid wrong panel putting and hand pressing 2.Double rail fast end cutting ----Improve efficiency 3.Pneumatic pressing 4.Pre-milling ---- Milling the damaged part of the plate edge to achieve better edge sealing effect 5.Double glue pot ---- Save time and increase efficiency 6.Four heads corner trimming ---- Improve efficiency and effectiveness 7.Coding precise control --- Precisely control tape cutting and conveyor,saving edge tape 8.Pneumatic double trimming --- Better trimming and higher efficiency 9.Auxiliary feeding --- Optional for narrow plate safe feeding 10.Pneumatic scraping 11.Fracture wire and pneumatic polishing --- Pneumatic swing polishing better effect;Remove the shaved wire, avoid twining on the buffing wheels caused the motor stalled and burned out. 12.Automatic knife adjustment system --- No professional engineer required to adjust the machine |

Model | GC-EB |

Function | For edge banding machine, we have basis function: Gluing, End cutting, Fine trimming, Rough trimming, Scraping, Buffing. |

Banding Tape Thickness | 0.4-3mm |

Banding Tape Width | 12-65mm |

Workpiece Thickness | 10-60mm |

Workpiece Length | >=100mm |

Workpiece Width | >=50mm |

Heating Power | 1.8kw |

Feeding Motor Power | 3.7kw |

Glue Spreading Motor Power | 0.75kw |

End Trimming Motor Power | 0.5kw x 2 |

Rough Trimming Motor Power | 0.75kw x 2 |

Fine Trimming Motor Power | 0.75kw x 2 |

Corner Rounding Motor Power | 0.5 x 2 |

Polishing Motor Power | 0.37kw x 2 |

Feeding Speed | 10-23m/min |

Air Pressure | 0.8Mpa |

Overall Dimension | 5670 x 850 x 1520m |

Packing Size | 5700 x 880 x 1580mm |

N.W. | 2300kgs |

G.W. | 2450kgs |

Machine Features: 1.Full-automatic edge banding machine function include glue,head together,rough repair,refine,Scraping edgeand polishing. 2.Have good shape,reasonable layout,has sound arrester,dust collector and overload protection. 3.The main parts of the machine adopt steel plate by laser cutting,one time welded together,the body is firm and undeformed. 4.Can increase or decrease component structure according to actual demand. |

Company information

The company's workshop

Packaging and transportation

Customer feedback and our service

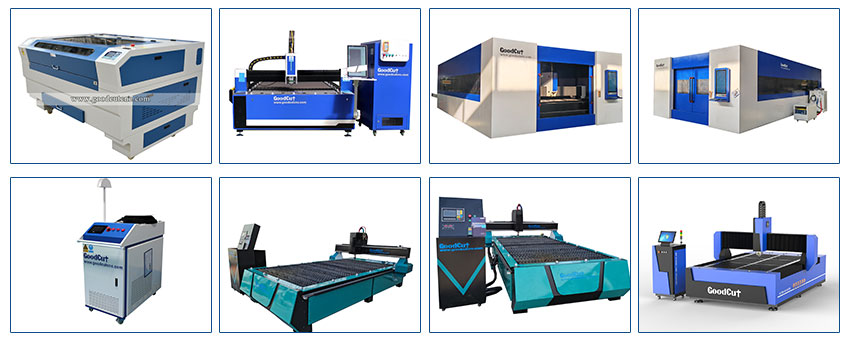

Equipment display

Group photo with our customer

Our qualification certificate

Contact: Candy Guan, Max Yuan

Phone: 008613170811607, 008618396850306

E-mail: candyguan@goodcutcnc.com

Whatsapp:008613170811607, 008618396850306

Add: A2 Block, Sanqing Shiji Caifu center, High-tech district, Jinan City, Shandong Province, China

We chat