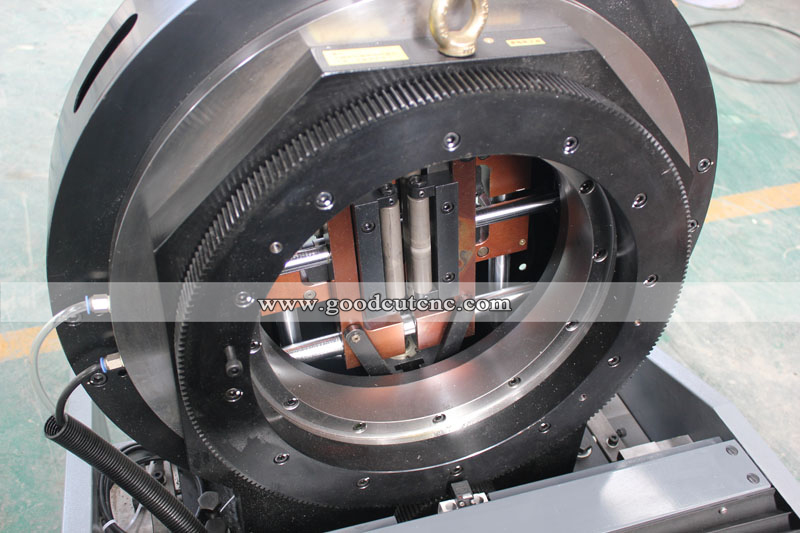

With rotary axis device

Both cutting plate and tube

Raycus/MAX/IPG laser source

Cypcut controller

Product description: 1500*3000mm plate working size 220mm diameter and 6m length rotary device With pneumatic chuck

GC1530FR Fiber Laser Cutting Machine with Rotary for Metall Plate and Tube

1.Controller | Cypcut control system -Which can realize intelligent layout of graphics,automatically choosing and matching cutting paths, save processing time |

2.Laser Source | Famous Brand Raycus / Maxphotonics -Solid state laser lasts over 50,000hrs; Various power options of 500w, 750w, 1000w,1500W,2000W,3000W etc |

3.Auto focusing | Capacitive Auto-height adjusting Raytools cutting headCutting Head -Focal point will be automatically adjusted in cutting process to achieve the best cutting effect of different thicknesses sheets metal. |

4.Servo system | Japan YASKAWA Servo driver and motor -With strong power and high precision |

5.Reducer | Japan Shimpo Reducer -The world best reducer brand.Used for replace traditional rack and belt,to make machine more powerful and stable |

6.High accuracy | Precision cutting -Which can reach ±0.02mm/300mm |

Feature:

1. Swiss Raytool brand Auto sensor laser cutting head. With Auto sensor system. Make sure cutting steel which is out of shape.

Inside laser head, with one collimating mirror, one focus lens and protect the mirror. At the bottom with copper nozzle, diameter mainly with 1.5mm diameter.

2.With CYPCUT Control system and software with the English language, applicable insert files with DXF Or AI format. Drawing in the software is also okay. Software with fly cutting mode for cutting the same products to save time. With Nesting function, automatic compose type for saving materials by saving spaces.

3. When laser head cut metals, there will produce some hot energy in the laser head and laser source. A water chiller is for cooling the mirrors and cooling the laser source. The temperature in the water chiller is an auto adjustment, mainly set up with 25-degree around water in chiller should be pure water

4. Chinese best brand Raycus laser device 500W-6000W: Applicable for cut high reflect materials like aluminum and copper. The photoelectric conversion more than 30%, Working environment: 10-40 degrees. Device with air-conditioning to keep it at normal temperature.

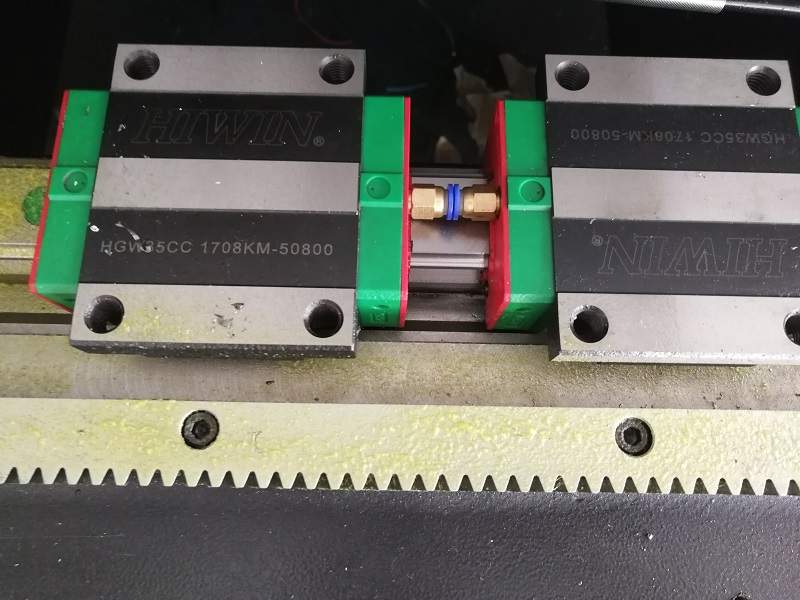

5. Gear- rack transmission system which with Germany brand rails. X and Y axis Moving speed can max 80m/min.

6. Big torque Japanese Yaskawa drive motors. Match-able with the transmission system, improve cutting speed and precision

7. At the bottom of the machine, with the collector for saving small cutting pieces. Below collector with wheels, easy push and pull.

8. The purging system is designed inside the machine bed. So make sure the smoke is absorbed immediately after cutting. Protect the air environment is also very important.

9. Feeding system with rolls. It is easy to load heavy sheet and metal sheets can be protected by avoiding scratched

10. Gear-rack and guide rails after using some time always need to be maintained by injecting oils to make sure the machine keeps moving fluently and in good precision.

11. X-axis beam is aircraft-grad

Roytools Laser Head

Switzerland Roytools Laser Head high stability and high sealing.

Laser head with Anti-crash function, Good sealed, high pressure resistant, auto-tracking system and anti-crash and stop system can

protect good cutting quality and longer the life of lens.

Taiwan APEX Gear Rack

Taiwan APEX hight precision rack grade 5 precision

Can be perfect for laser cutting machine.It can provide rigid. Support for quenching bevel gear and grinding belvel gear.

The bed is welded from thick steel pipes. The bed is annealed to eliminate excess hard force, increase the ductility of the bed, and ensure stability during the cutting process.

Japan Shjmpo reducer

Taiwan Hiwin huide rail

Cypcut controller

Raycus / IPG laser source

Contact: Candy Guan, Max Yuan

Phone: 008613170811607, 008618396850306

E-mail: candyguan@goodcutcnc.com

Whatsapp:008613170811607, 008618396850306

Add: A2 Block, Sanqing Shiji Caifu center, High-tech district, Jinan City, Shandong Province, China

We chat