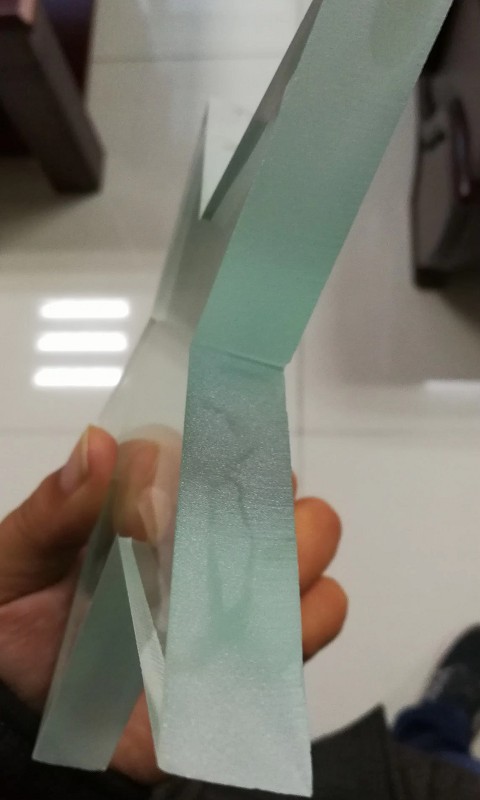

4000x2000x200mm(bevel 45 degree)

A-axis: ±75°

C-axis: ±720°

WEIHONG Control system

YASKAWA servo motor and driver

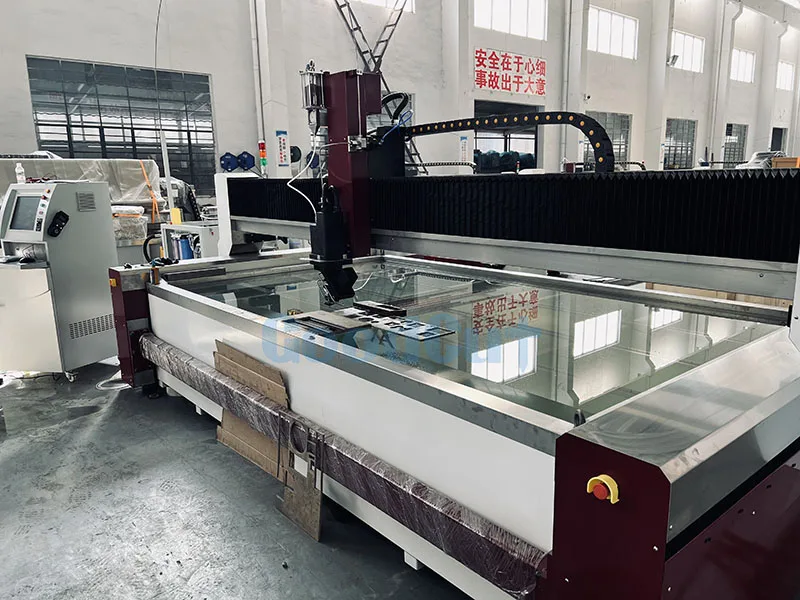

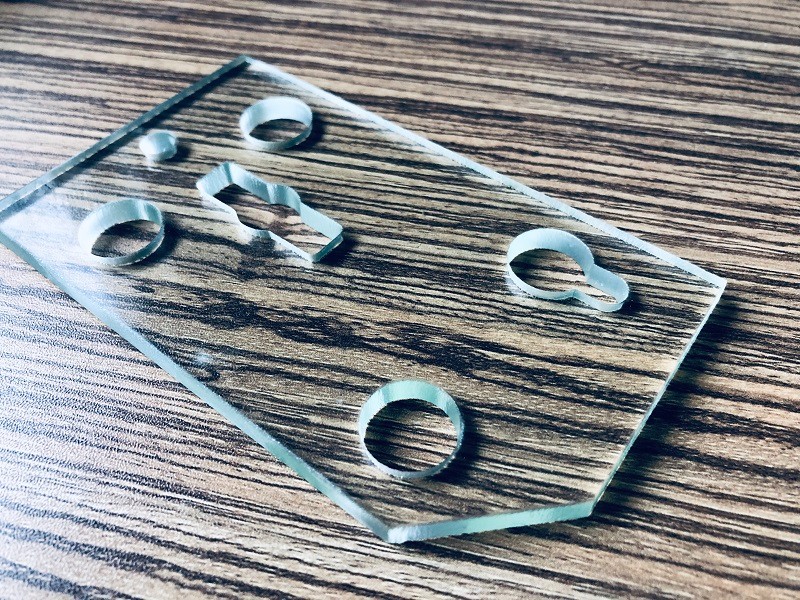

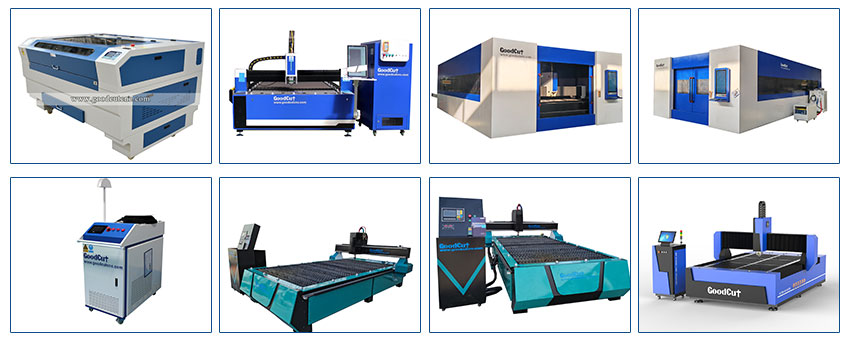

GC4020WJ-5A 3 axis 5 axis CNC Waterjet Cutting Machine for cutting Glass Stone Metal

CNC water-jet cutting machine is composed with cutting table, HP pump, CNC control system with waterjet cutting software, cutting head, Hp water valve, and sand controlling system . Auto abrasive feeding system and water cooling system are needed. Also you can choose optional systems such as water softening system and auto sludge removal system according your requests.

Model | GC4020WJ-5A |

Structure | Split Gantry Type |

X axis | 4000mm |

Y axis | 2000mm |

Z-axis | 300mm |

A-axis | ±75° |

C-axis | ±720° |

Effective cutting area | 4000×2000mm(bevel 45 degree) |

Control accuracy | ±0.01mm |

Repeatability accuracy | 0.02mm |

Running Speed | 15m/min |

Power | 380VAC, 50Hz , 3 phase 4 wire system(can be customized) |

Configuration of China 3 axis 5 axis cnc waterjet cutting machine for cutting Glass stone metal

1.1.2 Structure feature

- The machine body with the welding box structure, then make stress relief by annealing process.

- Table body and water tank which are split structure, lessen the splash of sands and water into moving parts, It is also conducive to the disassembly and transportation of the machine.

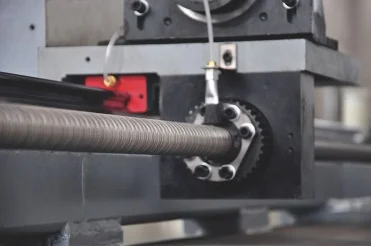

- X-axis and Y-axis transmit to rolling ball screw mandrel.

1.1.3 Controlling system

We adopt the WEIHONG controlling system based on the ADVANTECH industry computer,

YASKAWA digit servo driver and motor.

1.1.4Transmission system

- We adopt HIWIN linear guide rail and TBI ball screw to ensure accuracy and quality.

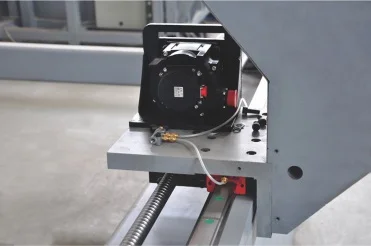

1.1.5Prevention system

- Over travel auto spacing function and soft spacing function

- Unique prevention design: new mazy protection and z-axis totally enclosed professional design prevent sand and water from eroding the guide screw and linear guide rail.

1.1.6Lubrication system

- We adopt auto mass lubrication system to make oil reach every oil site on time and also make table steadier and easier.

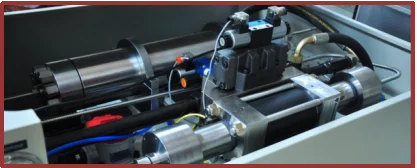

1: Hydraulic Intensifier Pump

1. High energy conversion efficiency, sixty percent energy saving than conventional pumps.

2. More stable output and higher

quality cutting effect

3. Fast starting speed, improve cutting efficiency.

2: WEIHONG CNC Controller

1.Especially present good quality in details of cutting, optimized the trailing made by water stream.

2. Easy draw with point, arc, polyline, shapes, ellipse, polygon, text.

3.Equipped with WEIHONG system as standard, high applicability to meet customer's cutting needs

- 17”LCD touch screen display

- DNC on-line working function

- Functions of returning arbitrary point, bending,

and circular arc working auto deceleration.

- Function of cutting figure imitation display.

- 80GB memory hard disk

- MITSUBISHI AC servo driver and motor.

-1GB memory card

- Multilingual function(Chinese English ,etc.,)

- Drive-by-wire and hand-hold controller,(according to requests)

3: Abrasive Delivery System

1. Provide abrasives for water jet cutting machine.

2. It can improve the automation of the machine and reduce the labor intensity

of the operator.

3. High-precision sensor reminds the operator when to replenish the abrasive material.

4. No need for electric

control, simple, reliable and maintenance-free operation.

4: Software-NcStudio

NcStudio PCIMC-6A special software is special for GC.

The functions of PCIMC-6A are as follows:

- Change DXF document which is educed from AUTOCAD

into numerical control process.

- Serial communications between PC and CNC.

- Open database can shore parameter, just click the material,

prameter will be loaded automatically

- Calculate length of line and time automatically

- Control cut-out and cut-in automatically

- cutting track auto imitation function

- The functions of lessening speed on the corner remanding material bridging and lancing

5: Water soften system

Here are many kinds of compounds in the running water.

(Calcium carbonate, carbonic acid)As the machine

working, the raising of the temperature will generate

some substance of the reaction of chemistry or physics-as

we called it furring, which will reduce the life of the high

pressure system and increase the cost. After many years’

experiences, the system can solve the problem.

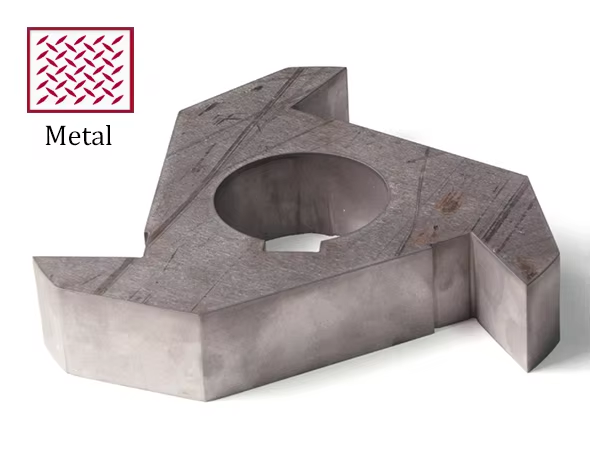

.Applicable materials :stone,granite, marble , metal. glass

The company's workshop

Packaging and transportation

Customer feedback and our service

Equipment display

Group photo with our customer

Our qualification certificate

Contact: Candy Guan, Max Yuan

Phone: 008613170811607, 008618396850306

E-mail: candyguan@goodcutcnc.com

Whatsapp:008613170811607, 008618396850306

Add: A2 Block, Sanqing Shiji Caifu center, High-tech district, Jinan City, Shandong Province, China

We chat