Machine price: 11000$-20000$

Working area:1500*6000mm

Laser source: raycus/MAX/IPG

Laser power:1KW-12KW

Motor and driver: Japan fuji / Yaskawa

Control system: cypcut

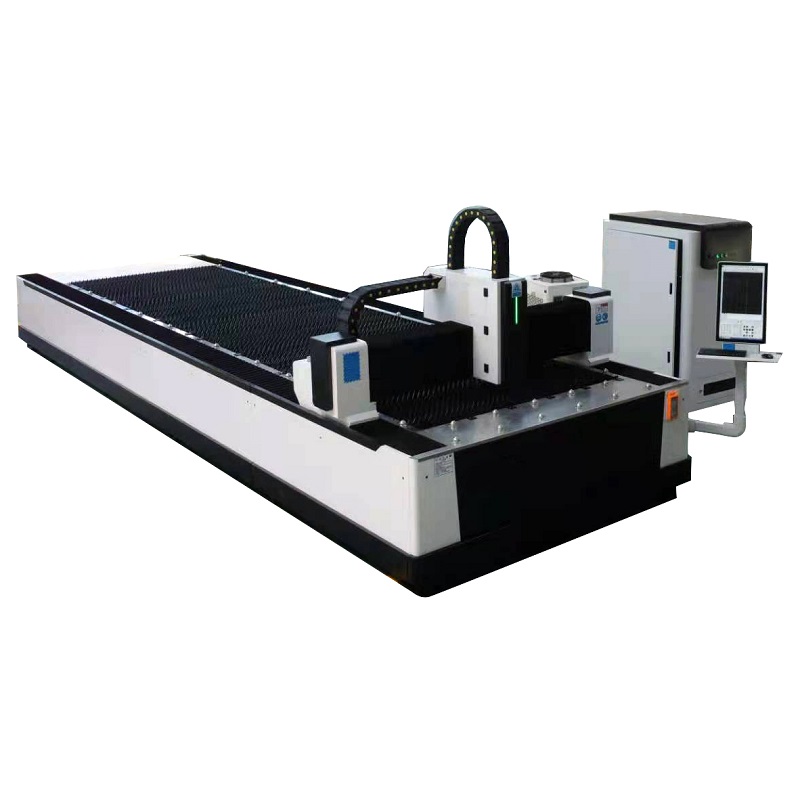

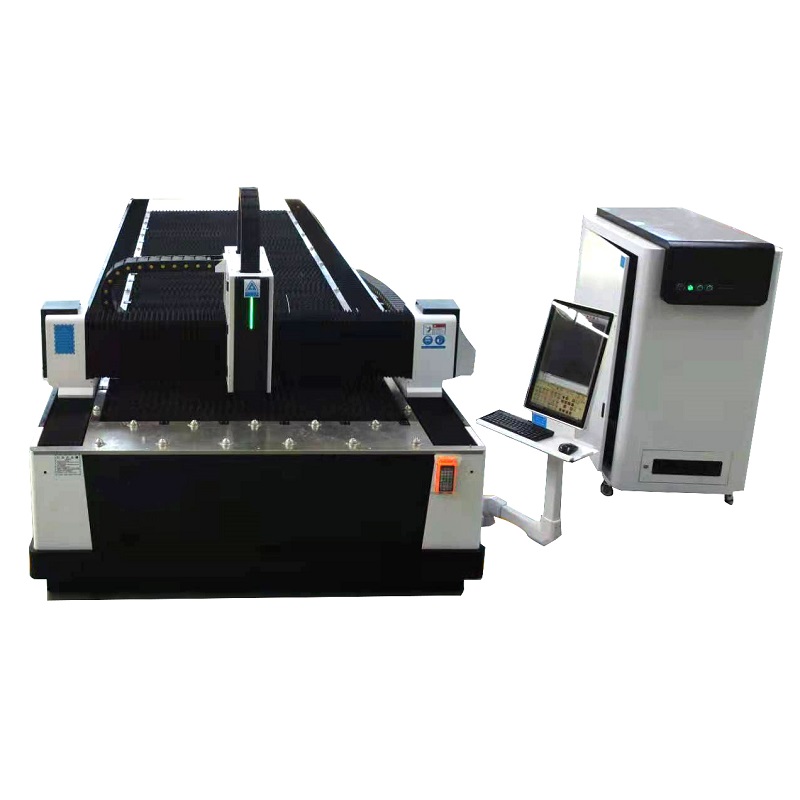

GC1560F fiber laser cutting machine for cutter carbon steel and stainless steel

GC1560F fiber laser cutting machine for cutter carbon steel and stainless steel:

1. Working area you can choose 3015/4015/6015/8015

2. Fiber laser power : 1000W, 1500W, 2000W, 3000W, 4000W, 6000w, etc.

3. Fiber laser generator brand :JPT, RAYCUS, MAX, NIGHT, IPG etc.

4. Laser cutting head you can choose Raytools/wsx/precitec ect.

5. Please contact us for other customization requirements

Main Features of GC1530F fiber laser cutting machine for cutter carbon steel and stainless steel:

1. Fiber laser cutter power: 500W, 750W, 800W, 1000W, 1500W, 2000W, 3000W, 4000W, 6000w, 10000w, 12000w, etc.

2. Fiber laser generator: JPT, RAYCUS, MAX, NIGHT, IPG etc.

3. Fiber laser cutter materials: Iron, aluminum, carbon steel, stainless steel, copper, hardware and another metal sheet materials.

4. Other machine optional parts can be chosen, such as, rotary axis, exchange working table, full cover, etc.

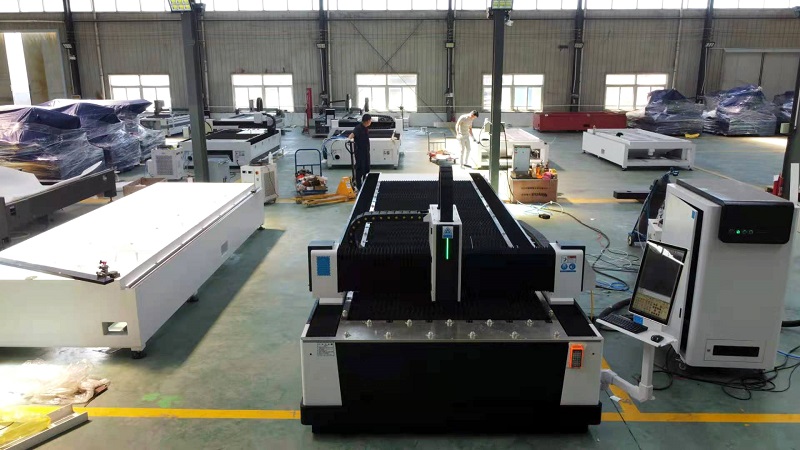

5. China Top fiber laser machine cutting manufactuers, JNLINK, best price and high quality, with CE etc certificates.

Machine Features of GC1560F fiber laser cutting machine for cutter carbon steel and stainless steel:

1. High-performance laser device associated with stable operation system enables optimal cutting effects.

2. Perfect cooling, lubrication and dedusting systems ensure stable, efficient and durable performance of the whole machine.

3. Single countertop make plates loading and unloading available during cutting, which improves the processing eficiency.

4. Large-size closed enclosure improves dedusting effects and avoids optical pollution.

5. Automatic height-adjustment performance keeps constant focal length and stable cutting quality.

6. Gantry structure and inblock aluminum cast cross beam make the device highly rigid, stable and antiknock.

7. It could ut mental in various materials and realize excellent and stable cutting effects.

DESCRIPTION of GC1560F fiber laser cutting machine for cutter carbon steel and stainless steel:

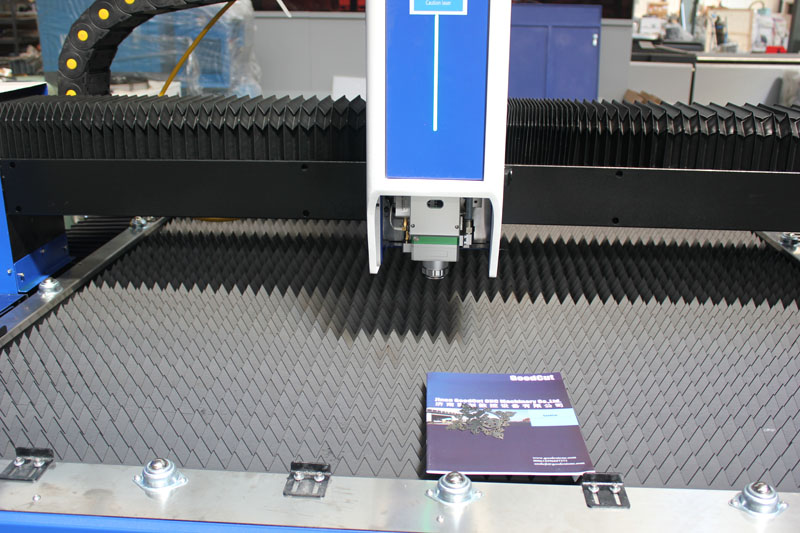

Roytools Laser Head:

Switzerland Roytools Laser Head high stability and high sealing.

Laser head with Anti-crash function, Good sealed, high pressure resistant, auto-tracking system and anti-crash and stop system can protect good cutting quality and longer the life of lens.

The bed is welded from thick steel pipes. The bed is annealed to eliminate excess hard force, increase the ductility of the bed, and ensure stability during the cutting process.

High quality carbon steel welding bed, high temperature annealing treatment, reduce the internal stress and deformation, its rigidity is strong, high structural stability.

we optimize the structure, perfectly integrate the workbench and bed, and directly put the knife blade on the bed to avoid shaking.

PARAMENTERS

| Product Features | |

| *Product Name | 1000w 1500w 2000w 3000w 6000w metal cnc fiber laser cutter laser cutting machine for iron steel aluminum copper plate sheet |

| *Brand | GoodCut |

| *Model | GC6015F |

| *Laser power | 1000W/1500W/2000W/3000W/4000W/6000W |

| *Working Area | 3000X1500MM, customized sizes are welcomed |

| *Cutting Thickness | 0.2-20mm |

| *Cutting Speed | 1-50m |

| *Cooling Way | water cooling |

| *Processing Material | stainless steel/carbon steel/galvanized steel/aluminum/copper/iron and so on all kinds of metal |

| *Laser head | raytools |

| *Laser source | raycus |

Product Description

The series of pioneer GC-6015D laser cutting machine offers power ranges between 2000W to 15000W. One of the most efficient machine technologies for rapid sheet metal cutting which can cut the thickness for 50mm or less.

1. Saving Material ---- CNC control, it can cut the material in different shapes, improve the utilization rate and reduce waste.

2.Easy Programme ----high accuracy, cut to shape without molding, smooth finish, eliminating the process for edge modification.

3. Save Investment for Molding ---- Laser cutting without molding, eliminating the cost for molding and repair, save time, resulting in less manufacturing cost, reduce the cost of goods sold, particularly suitable for processing parts in large-size.

4. Protecting Environment ---- working area for laser cutting is fully enclosed, low noise, is clean, safe, free of pollution, totally improve the working condition and environment.

![]()

Contact: Candy Guan, Max Yuan

Phone: 008613170811607, 008618396850306

E-mail: candyguan@goodcutcnc.com

Whatsapp:008613170811607, 008618396850306

Add: A2 Block, Sanqing Shiji Caifu center, High-tech district, Jinan City, Shandong Province, China

We chat